Heavy duty key locking inserts provide high strength and are designed to provide high resistance to rotation and pullout loads. Après l’installation dans le trou taraudé, Les clés de verrouillage de chaque insertion de clés sont enfoncées vers le bas à travers les filetages du matériau parent, locking the insert firmly and permanently in place.Available in inch and metric thread sizes, the stainless steel solid bushing configuration of the Keys inserts guarantees the quality of the internal thread before installation. No special tools are required for installation and standard taps and drills are used for hole preparation. The pre-assembled self-broaching keys set the insert to depth and ensure positive resistance against rotation.

Matériel: In Carbon Steel – C1215 or equivalent ; En acier inoxydable – 303 ou équivalent

Clés – 302 CRES ou équivalent

Finir: Acier au carbone – Zinc Phosphate ; Inox – Passivé

Tolérances: ±.010 pouce ou ±,25 mm, sauf indication contraire.

| Part number | Taille | |||||

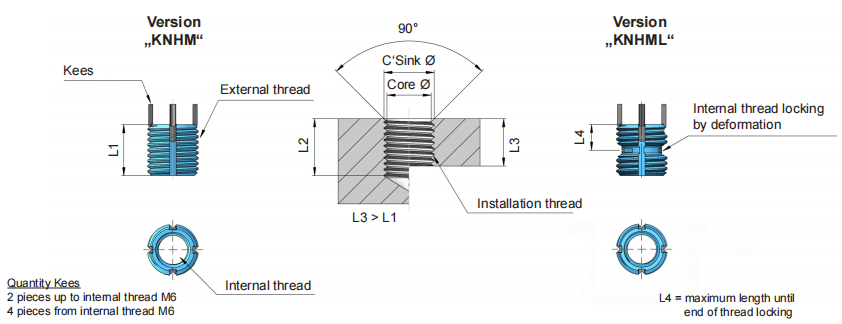

| Standard “KNHM” | Self-locking “KNHML” | Internal thread Ø Tol.- 5H | External thread Ø Tol.- 4h | Shear engagement mm² | L1

± 0,3 |

L4 |

| KNHM4X0,7 |

M4X0,7 |

M8X1,25 |

104,9 |

8 |

||

| KNHML4X0,7 | 83,1 | 8,0 | ||||

| KNHM5X0,8 |

M5X0,8 |

M10X1,25 |

177,7 |

10 |

||

| KNHML5X0,8 | 152,7 | 8,7 | ||||

| KNHM6X1,0 |

M6X1,0 |

M12X1,25 |

266,7 |

12 |

||

| KNHML6X1,0 | 242,5 | 9,5 | ||||

| KNHM8X1,25 |

M8X1,25 |

M14X1,5 |

341,6 |

14 |

||

| KNHML8X1,25 | 316,4 | 10,0 | ||||

| KNHM10X1,5 |

M10X1,5 |

M16X1,5 |

470,2 |

16 |

||

| KNHML10X1,5 | 441,4 | 10,0 | ||||

| KNHM12X1,75 |

M12X1,75 |

M18X1,5 |

608,5 |

18 |

||

| KNHML12X1,75 | 561,8 | 10,7 | ||||

| Part number | Taille | |||||

| Standard “KNHM” | Self-locking “KNHML” | Internal thread Ø Tol.- 5H | External thread Ø Tol.- 4h | Shear engagement mm² | L1

± 0,3 |

L4 |

| KNHM14X2,0 |

M14X2,0 |

M20X1,5 |

770,5 |

20 |

||

| KNHML14X2,0 | 724,4 | 12,4 | ||||

| KNHM16X2,0 |

M16X2,0 |

M22X1,5 |

896,8 |

22 |

||

| KNHML16X2,0 | 855,2 | 12,4 | ||||

| KNHM18X1,5 |

M18X1,5 |

M24X1,5 |

1084,4 |

24 |

||

| KNHML18X1,5 | 1051,5 | 16,8 | ||||

| KNHM20X2,5 |

M20X2,5 |

M30X2,0 |

1774,3 |

30 |

||

| KNHML20X2,5 | 1736,4 | 17,5 | ||||

| KNHM24X3,0 |

M24X3,0 |

M33X2,0 |

2189,4 |

33 |

||

| KNHML24X3,0 | 2161,9 | 19,0 | ||||

|

Part number |

Installation dimensions | Removal dimensions | |||||

|

modified Core-Ø* |

C’Sink-Ø +0,25 |

Installation thread | Hand installation tool part-no. | Forer | |||

| Thread Tol.- 6H | Profondeur L2 min. | Ø | Profondeur | ||||

| KNHM4X0,7 | 6,90 +0,100

-0,025 |

8,25 |

M8X1,25 |

9,5 |

KRTM4-02 / KNT01- HM4X0,7AU |

5,5 |

4,00 |

| KNHML4X0,7 | |||||||

| KNHM5X0,8 | 8,80 +0,100

-0,025 |

10,25 |

M10X1,25 |

12,5 |

KRTM5-02 / KNT01- HM5X0,8AU |

7,5 |

4,75 |

| KNHML5X0,8 | |||||||

| KNHM6X1,0 | 10,80+0,100

-0,025 |

12,25 |

M12X1,25 |

14,5 |

KRTM6-02 / KNT01-HM6X1,0AU |

9,5 |

4,75 |

| KNHML6X1,0 | |||||||

| KNHM8X1,25 | 12,80+0,130

-0,025 |

14,25 |

M14X1,5 |

16,5 |

KRTM8-02 / KNT01-HM8X1,25AU |

11,5 |

4,75 |

| KNHML8X1,25 | |||||||

| KNHM10X1,5 | 14,75+0,130

-0,025 |

16,25 |

M16X1,5 |

18,5 |

KRTM10-02 / KNT01-HM10X1,5AU |

13,5 |

4,75 |

| KNHML10X1,5 | |||||||

| KNHM12X1,75 | 16,75+0,130

-0,025 |

18,25 |

M18X1,5 |

20,5 |

KRTM12-02 / KNT01-HM12X1,75AU |

15,5 |

4,75 |

| KNHML12X1,75 | |||||||

|

Part number |

Installation dimensions | Removal dimensions | |||||

|

modified Core-Ø* |

C’Sink-Ø +0,25 |

Installation thread | Hand installation tool part-no. | Forer | |||

| Thread Tol.- 6H | Profondeur L2 min. | Ø | Profondeur | ||||

| KNHM14X2,0 | 18,75+0,130

-0,025 |

20,25 |

M20X1,5 |

22,5 |

KRTM14-02 / KNT03- HM14X2,0AU |

17,50 |

4,75 |

| KNHML14X2,0 | |||||||

| KNHM16X2,0 | 20,50+0,130

-0,025 |

22,25 |

M22X1,5 |

24,5 |

KRTM16-02 / KNT03- HM16X2,0AU |

17,75 |

6,35 |

| KNHML16X2,0 | |||||||

| KNHM18X1,5 | 22,50+0,130

-0,025 |

24,25 |

M24X1,5 |

26,5 |

KRTM18-02 / KNT03- HM18X1,5AU |

19,75 |

6,35 |

| KNHML18X1,5 | |||||||

| KNHM20X2,5 | 28,00+0,130

-0,025 |

30,25 |

M30X2,0 |

34,5 |

KRTM20-02 / KNT03-HM20X2,5AU |

25,75 |

6,35 |

| KNHML20X2,5 | |||||||

| KNHM24X3,0 | 31,00+0,130

-0,025 |

33,25 |

M33X2,0 |

37,5 |

KNT03-HM24X3,0AU |

28,75 |

6,35 |

| KNHML24X3,0 | |||||||

Chine Inserts filetés Fabricants

Chine Inserts filetés Fabricants

WeChat

Scannez le QR Code avec wechat